Microsoft Dynamics 365 Business Central is an enterprise resource planning (ERP) system that can help automate and streamline business processes, including inventory management. A major benefit of enhancing inventory management processes with ERP technology is the potential to improve profitability. Business Central inventory management features can help manufacturers across various industries leverage cloud-based technology to gain a clear view of goods from initial receipt to ship date.

Manufacturing inventory management includes tracking items from suppliers through multiple stages of production to the customer. Using ERP technology for inventory management can help manufacturers:

- Maintain detailed records of products and warehouses

- Track receipt, transfer, and delivery in real time

- Replenish stock levels at ideal intervals

- Reduce production costs

- Deliver on-time orders

How to Manage Inventory in Business Central

There are numerous philosophies on how to manage inventory in Business Central, but each includes these fundamental steps:

- Categorize your inventory – Everything starts at the item card. Item cards hold the information that’s required to buy, store, sell, deliver, and account for items. To enhance your overview of items and help you find them, you can categorize items based on item card fields, including variants, attributes, vendors, and stock-keeping units (SKUs). Then, you can categorize your inventory into groups.

- Analyze your inventory – When your inventory is categorized, you can quickly identify which items to order more frequently, which items often encounter shipping delays, and more. In addition, knowing what you have on hand versus what you think you have can significantly impact orders. Instituting cycle counting to confirm that physical inventory counts match inventory records can help you find and correct any inventory record discrepancies. Business Central has tools that can help support cycle counts and maintain accurate inventory management records.

- Document transactions – If an inventory transaction happens in real life, it should happen in your ERP system at roughly the same time. Promising a customer a product you think you have on hand—only to later find out the product is already spoken for—isn’t ideal. Business Central can help you track and manage transactions based on SKU and location information.

Breaking Down the Workflow

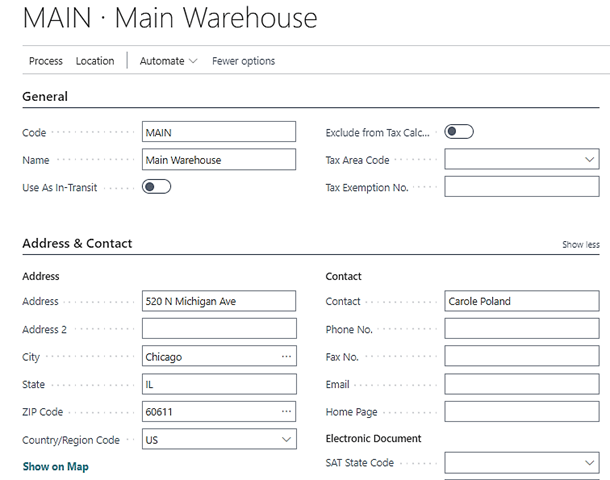

In addition to item cards, you can create location cards in Business Central. A location can be a specific warehouse. Depending on how complex your warehouse operations are, you can create multiple locations and then further divide a location into zones and bins.

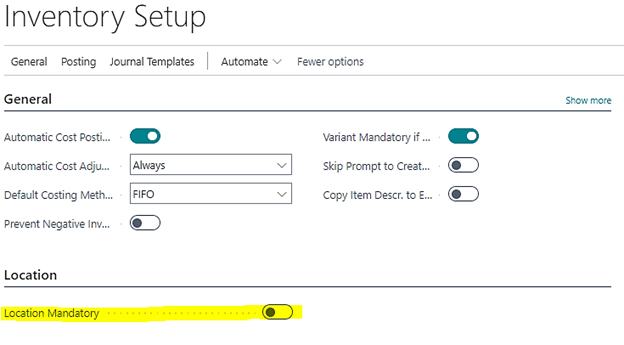

If you need to create more than one location, it’s recommended to set “Location Mandatory” on the Inventory Setup page to “True.” This will force your Business Central users to identify the specific location of inventory transactions.

Many fields on a location card are related to the handling of items in inbound and outbound warehouse processes. This is where you can organize the complexity of your warehouse operations in your ERP system. You can give each location a name and a code that represents the location. You then can enter the location code in other parts of the system when you want to record transactions for a given location.

You also can enter information about bins and warehouse policies for each location. Based on your warehouse processes, you can use the options on the “Bins” FastTab to specify the bins to use by default for transactions. If you want to structure your bins under zones, you can do that in Business Central, too.

The main takeaway is that location cards can store a lot of useful information to help streamline warehouse and inventory management processes in your ERP system. See a relatively simple location card example below.

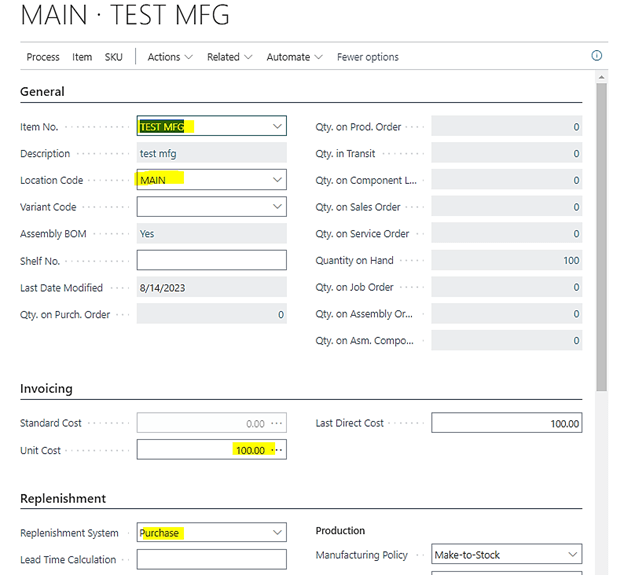

Going further, adding SKU information with location information in Business Central can help users manage similar item numbers across multiple inventory locations. In Business Central, SKUs are a supplement to item cards. SKUs can be used to record information about items for a specific location or variant (such as different shelf numbers or replenishment information for the same item).

It’s important to understand the relationship between SKUs and item cards. SKU data has priority over item card data for the specific location to which the SKU is linked.

In the example below, the SKU for item “Test MFG” is linked to the “MAIN” location.

The ability to have location-specific policies for specific items is a powerful Business Central feature. For example, an item could be purchased in one location but then manufactured in another location within one company. Another example is when one location has less raw goods storage onsite; its planning parameters (safety stock, minimum, maximum, etc.) can be completely different from another location that purchases more of the same material from the same vendor. Differentiating the same item at different locations is an advantageous feature that can help manufacturers streamline inventory management processes.

Bottom Line

Effective manufacturing inventory management can help reduce production costs and enhance overall operations. A little bit of time spent organizing data in Business Central can potentially lead to short- and long-term gains. Establishing efficient manufacturing inventory management processes can help businesses properly forecast inventory levels and consistently meet customer demand and expectations. By putting these key elements in place, you can be on your way to learning how to manage inventory in Business Central effectively and helping to improve visibility and profitability.

If you have questions or need assistance, please reach out to a professional at FORVIS or submit the Contact Us form below.