Cloud-based technology can help manufacturers meet increasing demands for expanded production and faster service. Microsoft Dynamics 365 is a portfolio of cloud-based business applications that supports operational efficiency and personalized customer experiences. Microsoft Dynamics 365 for manufacturing can help companies become more agile and reduce complexity and risk. Discover how manufacturers use Dynamics 365 applications to help meet customer demands proactively.

Manage the Asset Life Cycle

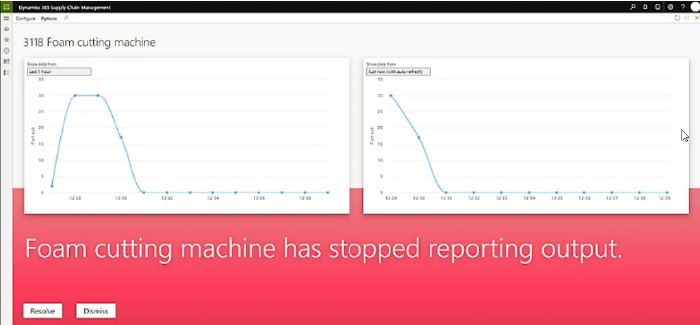

Effective asset life cycle management can extend asset lifespans and reduce maintenance costs. With Microsoft Supply Chain Platform AI-powered scheduling, sensor data, and mixed reality, manufacturers can perform predictive maintenance, which can help improve overall equipment effectiveness and reduce equipment downtime.

With data securely stored in the cloud, manufacturers have access to real-time operational information to help them make informed decisions. In industries where equipment plays a direct role in operational output, having the ability to streamline and automate maintenance schedules and send scenario-driven alerts based on preventive maintenance plans can help create significant cost savings.

Adapt Faster with Data Analytics

Data analytics are key to improving performance in the manufacturing industry. Disruptions to supply and demand require companies to gain operational agility to quickly respond to and meet customers’ needs.

Dynamics 365 enables companies to create a digital supply chain to help improve end-to-end visibility. With Dynamics 365 applications, predictive models can be built, and advanced analytics can be performed. This can enable manufacturers to visualize fulfillment and identify areas where operational efficiencies can be gained.

As one example, discover how Tillamook—known for its cheese—enabled automation in its warehouse to meet demand and improve throughput by more than 50%.

Enhance Supply Planning

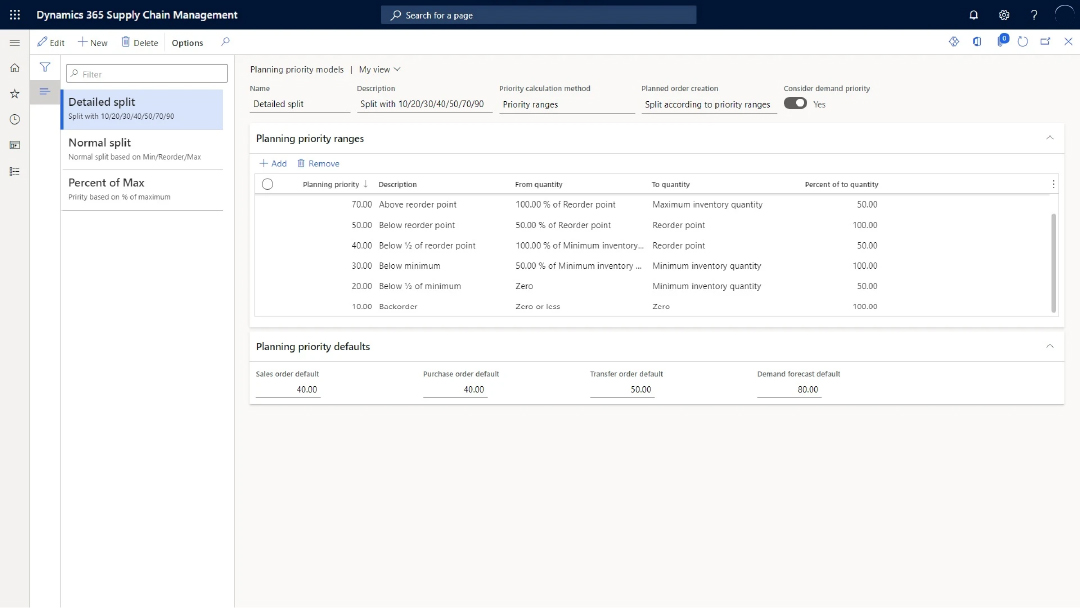

One of the challenges that manufacturers face when it comes to supply planning occurs when multiple orders for the same items land simultaneously, and there isn’t enough stock on hand to fulfill all the orders. Which distribution center or store orders should be filled and in what order? Which is most important and how should priority be set? While it's relatively easy for someone to manually review and determine planning priorities in these instances, manufacturers have lacked a systematic process to automate these decisions at scale.

To respond to this challenge, Microsoft introduced the Planning Optimization update for Dynamics 365 Supply Chain Management. This feature can be set to automatically prioritize replenishment orders so that urgent demand is prioritized over less-important demand. For example, a stockout replenishment order can be prioritized over a standard refill replenishment order.

Enabled settings also can let the system split larger orders into separate smaller orders, with order lines grouped by priority, and then process all high-priority orders first. This can reduce the risk of stockout by adjusting the use of available supply.

Automate Repetitive Tasks

Workplace automation can contribute to employee satisfaction by reducing time spent on repetitive tasks and increasing focus on innovation, safety, and value-added activities.

With low-code applications, manufacturers can streamline and automate manual processes, such as:

- Data entry from spreadsheets and PDFs

- Requesting and updating supplier information

- Securely storing signed documents

- Uploading form data

Often, the resources saved by automating manual processes lead to increased cost savings year after year.

Collaborate & Communicate Effectively

Earning high service ratings by predicting, detecting, and resolving service issues before customers even know there’s a problem can be a major competitive advantage for manufacturers.

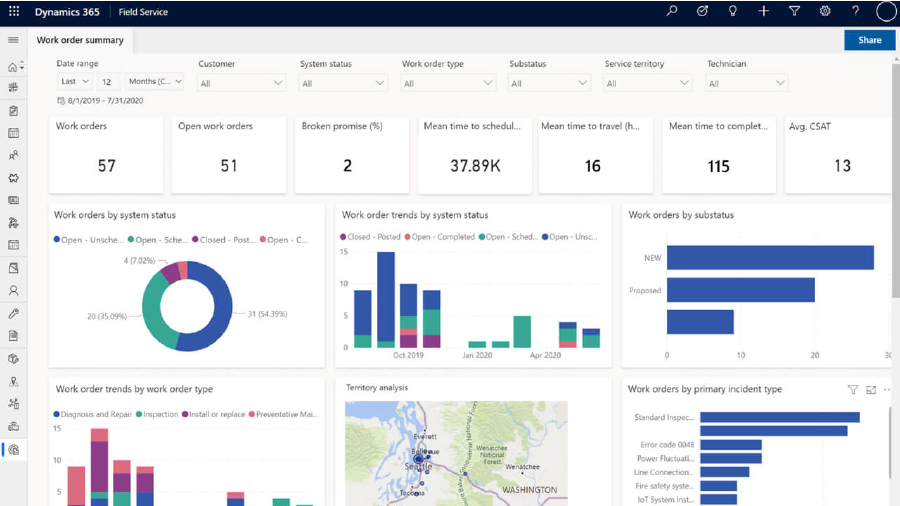

Beyond predictive analysis, Dynamics 365 enables teams to collaborate effectively with customers, suppliers, and logistic partners. Effective communication can elevate customer experiences and foster relationships. You can even help mitigate supply issues by collaborating with external suppliers through Microsoft Teams.

The Dynamics 365 Field Service application includes an in-depth set of service team scheduling capabilities. It can help improve productivity by leveraging connected tools and relevant work-order data so employees are well prepared for every service job. It also can find resources to help meet job needs by evaluating location, skills, and other characteristics and can provide near real-time service ratings.

See how G&J Pepsi-Cola Bottlers uses Dynamics 365 Field Service to proactively engage with customers.

What’s Possible

The examples above are only a few of the many ways manufacturers can use Dynamics 365. Cloud-based technology can help manufacturers increase factory agility and business resilience. By securely connecting manufacturing assets and creating a digital supply chain, operational visibility and productivity can be enhanced.

The Business Technology Solutions Team at FORVIS can assist you with unlocking value through manufacturing digital transformation. FORVIS is a Microsoft Dynamics Gold Partner and 2022-23 recipient of the Microsoft Inner Circle Award. We provide analysis, design, implementation, upgrades, training, and support services for Microsoft Dynamics business applications. Use the Contact Us form below to get in touch.